e Coating

Services

Electrocoating, commonly known as E-Coating, stands as a versatile and advanced method for providing durable and reliable corrosion protection to various metal surfaces. This electrochemical process has gained immense popularity across industries due to its effectiveness, efficiency, and environmentally-friendly nature.

The E-coating Process

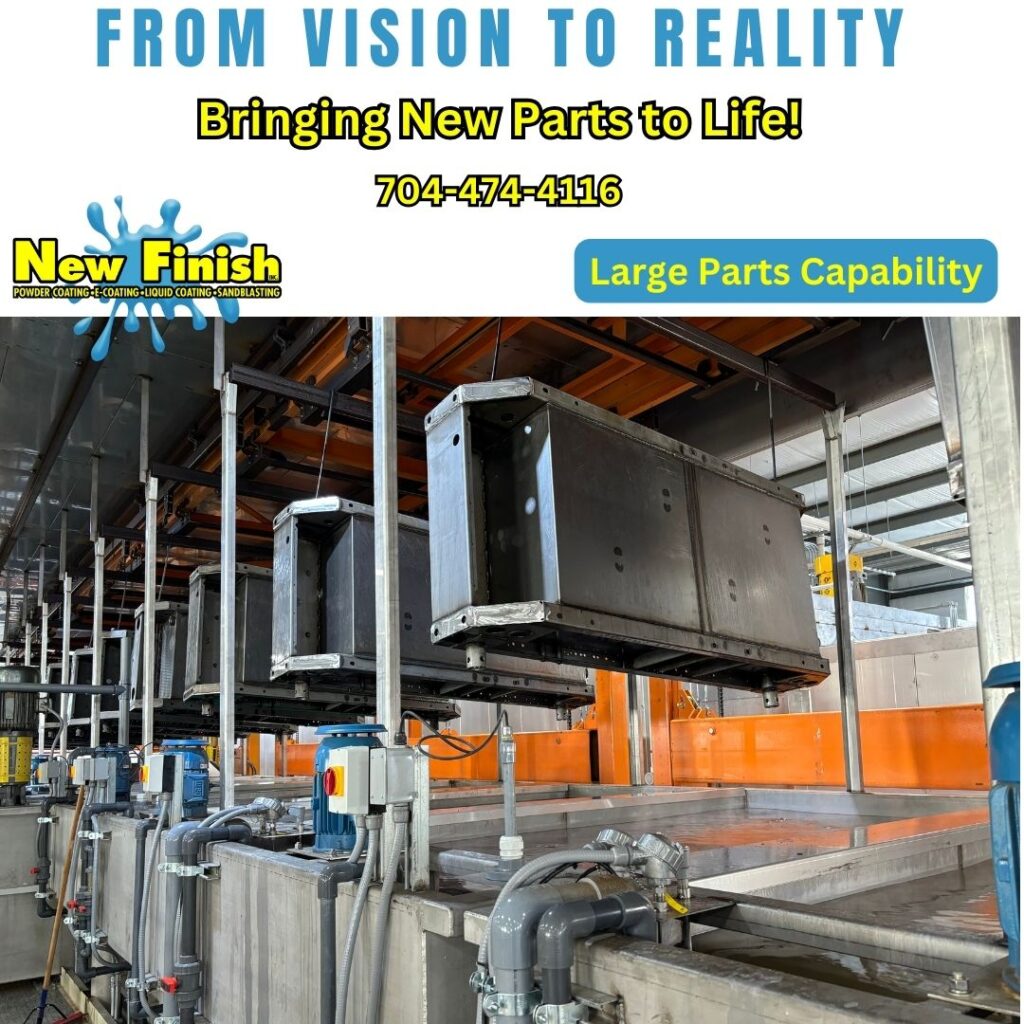

Our New E-Coating Line!

Experience the New Finish Difference:

New Finish provides unmatched coating expertise, automated processes, and value-added solutions for our customers.

8-Stage Pretreatment: With zinc phosphate and non-carom. System able to meet or exceed all e-coating specifications.

Zinc Sludge Removal System: On line zinc sludge removal system to maximize bath life.

Slide Transfer System: Slide transfer system provides complete process coverage for any configuration of parts

Cathodic Epoxy E-Coat: this material is the benchmark for corrosion resistance. Also provides consistent film builds over complex parts.

Coating: Coating thickness: .6-1.5 mils

Exploring the Benefits of E-Coating

Ultimate Corrosion Protection

Superior Corrosion Protection:

E-Coating forms a protective film on the metal substrate that offers exceptional resistance to corrosion, even in harsh environments. The process involves immersing the metal parts in a bath of paint and applying an electric current. This creates a uniform and tightly bonded coating that covers every nook and cranny of the part’s surface, providing comprehensive protection.

Versatile Applications:

E-Coating finds applications across various industries, including automotive, appliances, aerospace, furniture, and more. It is particularly useful for parts that require complex shapes, such as vehicle frames, suspension components, and household appliances.

Adaptable Coating Properties:

E-Coating offers flexibility in terms of coating properties. By adjusting factors like voltage, bath chemistry, and process parameters, manufacturers can control the thickness, color, and performance characteristics of the coating to meet specific requirements.

Why E-Coating?

Longevity Durability

Thanks to its excellent adhesion and comprehensive coverage, E-Coating exhibits remarkable longevity. The coating’s resistance to chipping, cracking, and peeling ensures the coated parts remain protected for an extended period.

Enhanced Aesthetic Appeal

E-Coating produces a smooth and uniform finish that enhances the aesthetic appeal of the coated parts. The even coating thickness and controlled application contribute to a visually pleasing appearance that is often difficult to achieve with other coating methods.

Cost Effective

While the initial setup for E-Coating may require some investment, the process is highly automated and efficient, leading to reduced labor costs over time. The uniform coverage also minimizes the need for touch-ups or rework, further lowering maintenance expenses.

Environmental

E-Coating is known for its minimal environmental impact. The process uses water-based paint formulations, which release fewer volatile organic compounds (VOCs) compared to solvent-based coatings. Additionally, the efficiency of the E-Coating process reduces waste and overspray, making it a sustainable choice.

New Finish Recent News

Heavy-Duty Industrial Coatings for Construction & Heavy Equipment Companies

In the construction industry, equipment takes a beating—day after day, job after job. That’s why manufacturers, contractors, and OEMs turn to New Finish, Inc. for heavy-duty powder coating, liquid coating, and E-coating solutions that offer real protection in the real...

Supplying the Large Trucking Industry with Reliable, High-Performance Parts Coatings Across NC, SC, and VA

At New Finish, Inc., we proudly serve the large trucking industry by providing high-performance, ISO-certified industrial coatings for heavy-duty truck parts. Our facility, located in Stanly County, North Carolina, is uniquely positioned to support manufacturers,...

Protecting What Feeds America: Agricultural Equipment Coatings by New Finish, Inc.

Farmers and agricultural manufacturers know that equipment is a major investment—and that it’s constantly under attack by the elements. At New Finish, Inc., we specialize in coating solutions that protect agricultural equipment from rust, corrosion, UV exposure, and...

Professional Coating Services

Location

8353 Highway 52 South

Norwood, NC 28128

Call us

Phone: 704-474-4116

Fax: 704-474-0275